Stored cold is not a useful concept for dissipating 20 MW in a running reactor.

Didn't say it was. I thought there might be ideas concerning design and insulation concepts that might be useful.

Unless the plan is to run the reactor for 5 or 10 - 1 sec pulses in a 10 hour period.

I doubt that was their concept but it's irrelevant since I'm not arguing their concept. Simply pointing out they may have some design/material concepts that might be useful.

In any case even 20 MJ for 1 second is likely to cause a superconductor explosion from stored magnetic energy.

Not arguing or advocating their concept. They thought perhaps they could stretch it into several hours which is why I pointed it out for the reasons mentioned above.

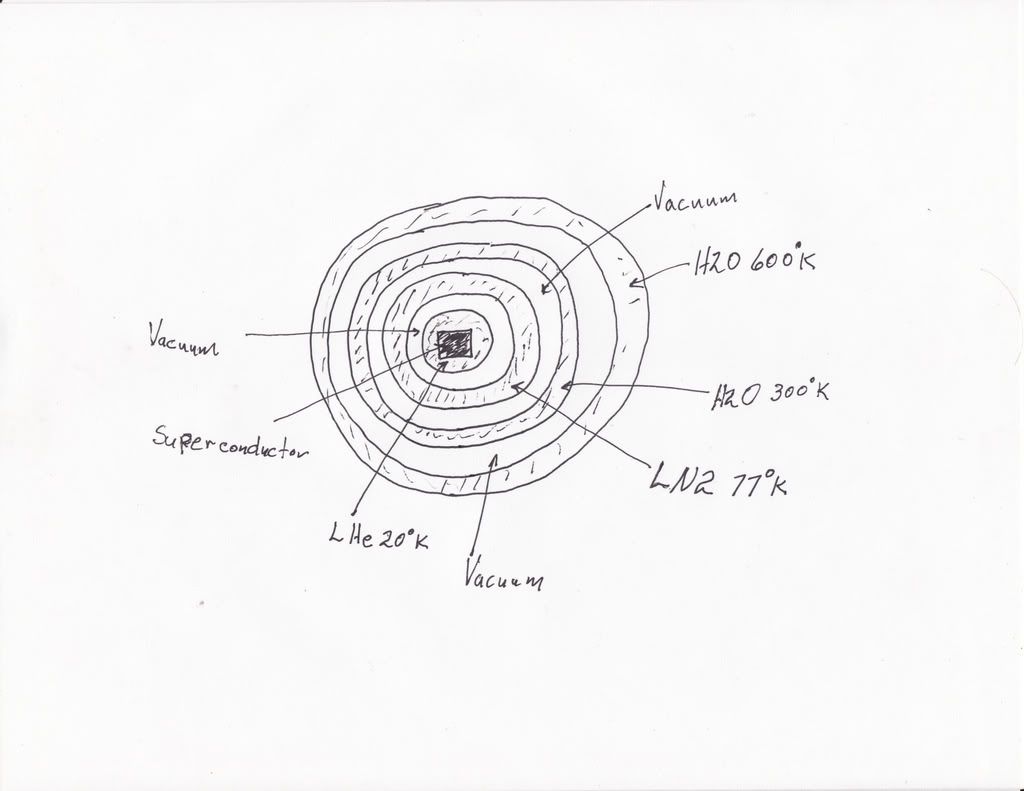

There is not going to be some magic bullet. We are going to have to extract the energy at around 600 deg K and keep the magnets below 20K. That is just a fact of life. It can be done (I'm convinced) it will just require some tricks - like an extra layer of coolant at 300K.

Which is why I originally mentioned this and the idea of a non conductive inner layer using a unpressurized coolant to take some of the load off the primary coil housing. I have no idea if such would be valuable or not but simply mentioned them to see if anyone found any value. My engineering never progressed beyond field fortifications or how to recover damaged armored vehicles in interesting circumstances.

The tough part will be getting all that squeezed in the right form factor.

Agreed.

Let me add that I do not in any way wish to discourage you from thinking of other concepts that might help. I will continue to raise objections (if I have any) until we come up with a good idea.

I have no animosity, unless you're secretly a sock puppet controlled by Paul Dietz.

Simply wasn't sure if I was making my reasoning plain in the earlier postings.

Science is hard. Engineering is harder.

I had more fun blowing things up. Artillery bursts in the dewy morning are beautiful. The momentary sphere of compressed moisture takes on a mirrored sheen for a fraction of a second. Quite surreal.

I always wanted to be a scientist when I grew up. I kind of fell into engineering. I think I like it better. The problems are harder.

I had neither the opportunity or resources. My oldest however is working on his masters program (not sure if he'll stay with mathematics or not). I have plans for my grandchildren, if health and resources hold out. If that seems domineering to some, well I grew up at a level of poverty few can even visualize, I will not have it happen to my decedents.

We are most fortunate that Dr. B was more of an engineer than a scientist. I'm sure he contemplated these problems and factored them into his research.

It would be interesting to see his private notes, if they're ever released. It is a bit concerning though in reference to mobile uses.