MSimon wrote:KitemanSA wrote:MSimon wrote: Good idea. Except that you would need some kind of custom manufacturing setup of considerable complexity to wind and impregnate the coils. Even square plan coils are going to (most likely) require several iterations to get it right. That is the beauty of MRI coils. They are already in production.

Not so difficult. Winding the two types of magnets (squares and triangles) is easy. Going with bow-legged squares and triangles vice straight legged would be mostly a wash in the winding. Soldering on the casing would be the hardest part, and that shouldn't be

too difficult for an accomplished solderer.

If you want to do LN cooled, we probably would be best served by going with the modified MPG winding method discussed in other posts. That would start getting complex, but I think it would still be doable. Again, the casing would be the hardest part.

I believe a little more study of the difficulties is in order. The quench problem is significant. And it has a lot to do with how the coils are made.

Of course if there are "unlimited" funds - no problem. Budget $5 million or $20 million for a custom winding facility and various tests to work out the bugs. Vs a million or two for off the shelf coils and a few hundred thousand for supports.

I have been wanting to bring this up, and since your message touches on it, now seems as good a time as any.

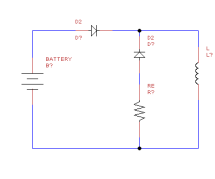

Back when I was looking at how difficult it would be for an amateur to build an experimental reactor, I was trying to learn how they "charge" a superconducting magnet. I found various sources that reiterated the idea of heating a portion of the magnet then applying a voltage across it. As it turns out, the people who manufacture these things, also manufacture machines (power supplies) that charge the superconductors. Apparently SuperConductors REALLY REALLY REALLY don't like changes in their magnetic field, and for this reason, the current must be built up very slowly. The machines for charging a superconducting magnet are designed to automatically ramp up the current at rates which are settable by the operator.

The part I found most interesting, and likewise most serious, is that superconductors REALLY REALLY REALLY don't like changes in their magnetic field. Ramp the field up too quickly, and the Magnet "quenches". Likewise, if you disturb the field too much, the magnet "quenches."

Apparently charging a superconducting magnet is a tricky business.

In this same pdf file, it mentioned that the problems of charging more than one superconductor in near proximity become compounded immensely! If the fields are capable of interacting, (an absolute given in a polywell) then any rapid increase (or decrease) in the field of one will quench them both. And this is just with TWO superconducting magnets ! Imagine the hassle with SIX !

In any case, it looks like someone is going to have to design a machine that can successfully charge six superconducting magnets at the same time, all in close proximity to each other. Sure, it's likely dooable, but it's just another layer of difficulty to deal with. By the way, if you charge up a superconducting magnet high enough, and then "quench" it, you are discharging all that energy into a no longer superconducting conductor. You can very easily "Fry" the magnet.

Another added difficulty is how to ramp up the wiffleball and alpha flow without creating a rapidbly changing magnetic field capable of quenching the magnets. (Remeber, if you quench any one of them, it will probably result in a cascade quenching of all the rest ! )

Can you imagine what would happen if you were operating a 100 MW polywell and the magnetic confinement suddenly quenched ? Tom Ligon's description of what happened with PXL something or other is probably a good indicator.

Something to think about. When I get more time, i'll try to find that Magnet charging operators manual I had found previously.

David