Page 1 of 1

Navy's new 36.5 MW superconducting motor Successfully Tested

Posted: Tue Jan 13, 2009 8:50 pm

by just_an_observer

Posted: Wed Jan 14, 2009 7:51 am

by MSimon

I blogged it and a few other good things about the future of an all electric Navy.

http://powerandcontrol.blogspot.com/200 ... -navy.html

Posted: Wed Jan 14, 2009 8:28 pm

by David_Jay

"I just love it when a plan comes together"

Okay, Hannibal

Posted: Fri Jan 16, 2009 12:34 am

by Tom Ligon

In 2001, we obtained a sample of HTS superconducting ribbon at the San Diego lab. The HTS material was sandwiched between two thin silver foil strips, and looked really delicate. About as far as I got with it was dunking a piece in LN2 and verifying it would levitate above a magnetic field. Dr. Bussard was not inclined to pursue building a magrid from it at that time.

Evidently, the technology is now considerably more mature. I wonder it the Navy would like to fund a HTS magrid on the WB7 scale, as an additional demonstration of the technology? It should perk up the function by B^4, and avoid the short run times due to lack of cooling in the present copper magnets.

It is not strictly necessary to the program, but it ought to work like gangbusters.

Posted: Fri Jan 16, 2009 1:08 am

by KitemanSA

Tom's suggestion is one of those things I think might be better done in another lab. Maybe we can get the Peninsula College group that made that fusor on a shoe-string to take on a bigger task.

Posted: Fri Jan 16, 2009 5:17 am

by TallDave

I assume this would need LN2 cooling, and would be a continuous operation device.

Might learn a lot that's useful. Would this be in the tens of millions range, do you think?

Posted: Fri Jan 16, 2009 5:52 am

by MSimon

TallDave wrote:I assume this would need LN2 cooling, and would be a continuous operation device.

Might learn a lot that's useful. Would this be in the tens of millions range, do you think?

The Polywell itself might only cost an extra million or two (engineering costs, material costs).

The big hit is going to be power supplies for continuous grid operation. If some of the extrapolations I have seen are correct - smaller machines will need bigger power supplies due to losses.

i.e. The same supplies might well work for WB-100.

BTW MgB currently (AFAIK) has the greatest neutron resistance. If the B was replaced by B11 neutron resistance might go up by a factor of 1,000.

BOE says MgB ought to be good for an hour of D-D. 350 10 second shots.

So MgB11 would be good for 1,000 hrs - 6,000 10 minute shots. Or 60,000 one minute shots.

BTW for our application HTS are not really HT. To get the fields desired they have to run at 4degK to 10degK. Which means MgB is as good as YBCuO from a field/temp perspective with better mechanical and neutron properties.

Posted: Sat Jan 17, 2009 3:25 am

by TallDave

Yeah, 5-10MW continuous power is going to cost a pretty penny.

BTW for our application HTS are not really HT. To get the fields desired they have to run at 4degK to 10degK. Which means MgB is as good as YBCuO from a field/temp perspective with better mechanical and neutron properties.

Hrm, I hadn't realized that. How many T could you get from HTW at LN2 temps, do you think? I assume we're talking ~70K.

It has to be fairly respectable if they power that 36.5MW motor, right?

Posted: Sat Jan 17, 2009 4:45 am

by MSimon

TallDave wrote:Yeah, 5-10MW continuous power is going to cost a pretty penny.

BTW for our application HTS are not really HT. To get the fields desired they have to run at 4degK to 10degK. Which means MgB is as good as YBCuO from a field/temp perspective with better mechanical and neutron properties.

Hrm, I hadn't realized that. How many T could you get from HTW at LN2 temps, do you think? I assume we're talking ~70K.

It has to be fairly respectable if they power that 36.5MW motor, right?

The motor is cooled with LHe.

http://nextbigfuture.com/2009/01/365-me ... motor.html

http://nextbigfuture.com/2009/01/365-me ... motor.html

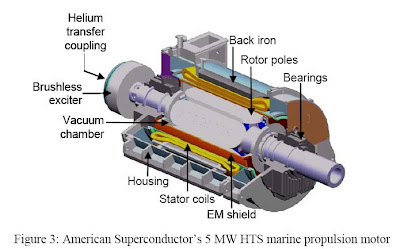

Note the Helium Transfer Coupling.

From:

http://www.amsc.com/products/motorsgene ... psASNE.pdf

This motor employs an HTS field winding that operates at ~32 K and is expected to weigh 75 tonnes, which includes the weight of its stator and rotor cooling equipment. The Detailed Design Review (DDR) of this motor was completed on October 6, 2004 with no discrepancies, and currently it is on schedule for delivery to ONR by fall-2006.

Posted: Sun Jan 25, 2009 7:42 pm

by Roger

Tom Ligon wrote:In 2001, ...

... The HTS material was ...

...and looked really delicate.

Evidently, the technology is now considerably more mature.

It is not strictly necessary to the program, but it ought to work like gangbusters.

KitemanSA wrote: Maybe we can get the Peninsula College group that made that fusor on a shoe-string to take on a bigger task.

At some point.....(assuming continued nuanced successes) Universities ought to be brought in, while funded research breaks up into parallel tracks. If you missed it a while back I found that high school kid who built a fusor, who then went to Georgia Tech where he built a better fusor. Well the kid is now I think on his 3rd or 4th machine.... and recently transfered to University of Wisconsin @ Madison to work under Dr Kulcinski.

His most recent iteration is a Flouro cooled grid. A "nuanced success", he's now building an ion gun to feed his FUSOR ON STEROIDS.

Tom Ligon wrote:

I wonder it the Navy would like to fund a HTS magrid on the WB7 scale, as an additional demonstration of the technology?

It is not strictly necessary to the program, but it ought to work like gangbusters.

Nothing like a little success to sweeten the game. I wonder if a University would like a few million to build a HTS magrid on the WB7 scale?

How about a HTS flouro cooled fusor ? I know about this kid who built a flouro cooled grided fusor... lol.